Steel MC C.A. is assuming the challenge to build a better world. We offer the ultimate Waste to Energy technology to the international market: Plasmatronic® AC Plasma Gasification. Plasmatronic® is the most accessible and effective waste to energy conversion technology in the market.

In partnership with the Institute of Electrophysics and Electric Power of the Russian Academy of Science – the IEE RAS – and International EPC companies, we assemble turnkey waste to energy projects with Plasmatronic® to secure social impact.

After more than 30 years of research, the IEE RAS is the world-leading institute in the development of plasma technologies (electrophysics, plasma physics, aerodynamics, power engineering and electrical engineering). Our exclusive partnership with the IEE RAS fully enables us to design, carry out, build equipment and train staff projects of Plasmatronic® AC Plasma Gasification worldwide.

We offer treatment solutions for waste to energy, supertoxic destruction and hazardous medical waste treatment. Our turnkey project services comprise research & development, engineering designs, construction, training and commissioning.

Plasmatronic® offers the opportunity for municipalities, companies and countries to become self-sufficient in their energy supply by converting their own waste into electricity or diesel. The composition of the SYNGAS can be compatible with different downstream processing systems. No water has to be pre-treated. It can also be combined with Natural Gas, for example, to take advantage of existing plants to optimize electric production. The use of multiple reactors for large projects improve and increase the overall gasification system and avoid any development risks. Take a tour of the plant the IEE RAS has had in operation since 2005 accompanied by IEE RAS Dr. Rutberg (feature by Technology Update ends 6:42”).

AC Plasma Gasification is a process that converts carbon (organic) materials such as municipal solid waste, and other types of waste such as coal, and petroleum into synthesis gas (syngas), under very controlled conditions of heat and oxygen. Plasma gasification is NOT combustion. The chemical reactions in the plasma gasification process converts waste or other materials into simple molecules and atoms, whereas incineration creates complex and toxic substances, including dioxins and furans.

Fourth state of the matter.

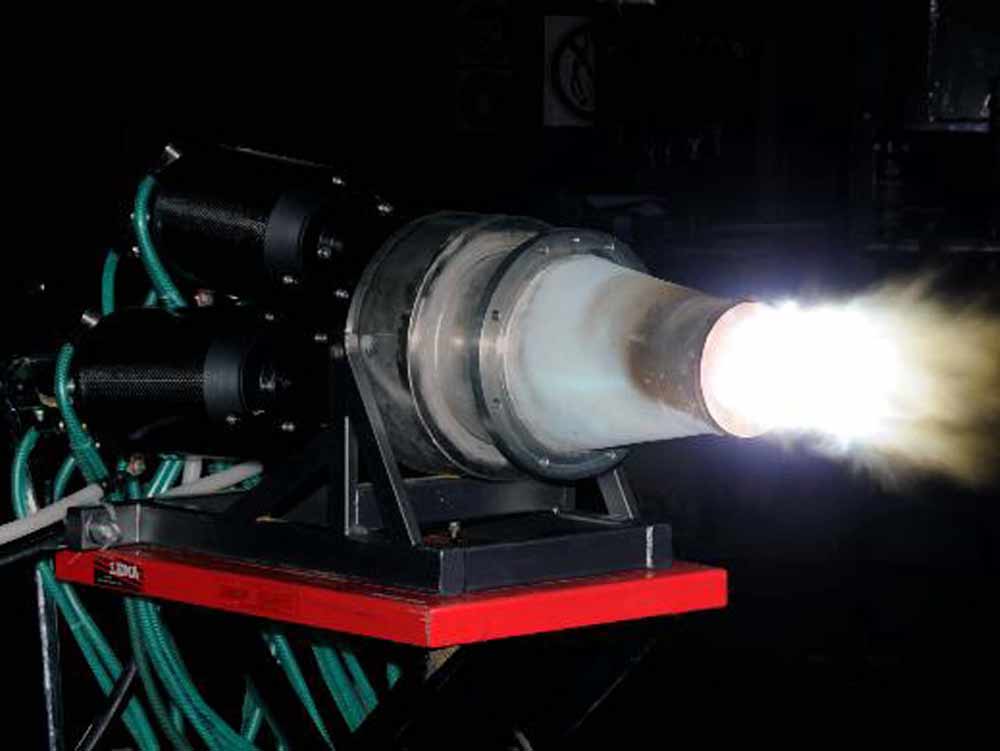

Only plasma technology to use alternating current torches (AC) rather than direct current torches (DC). This converts carbon content into Syntesis Gas (Syngas).

Mainly composed of CO and H.

As a result of AC torches, Plasmatronic® reaches high levels of efficiency (~94%).

A State of the Art and U.S.A. patented plasma gasification technology.

Plasmatronic® AC plasma gasification contributes to the reduction of emissions of greenhouse gases such as CO2 or CH4; recovers dumps and landfills; solves electric shortages and decreases the reliance on non-renewable resources.

With Plasmatronic® we can produce more electricity and more fuels than any other plasma gasification development.

Plasmatronic®’s ability to control the plasma and maintain it away from the chamber walls result in a cooler and more practical operating system. This allows the torches to work under extreme temperatures without affecting the outside temperature of the reactor. Losses that would otherwise occur in the power supply are dramatically reduced. The AC torches have an additional operational advantage of hundreds of hours without need for maintenance.

Plasmatronic® is able to convert waste to energy at the highest efficiency levels thanks to our patented Alternating Current (AC) torches system - at a rate of ~94% compared to Direct Current undisclosed percentage. AC torches increase efficiency and productivity, by reducing Direct Current-related instability, loss of power and O&M costs. The electrode lifespan of AC torches is up to 2,000 hours compared to <200 hours of DC torches.

Our mission is to support the world’s emerging and newly industrialized economies, so they can finally have access to alternative energy sources and cost efficient technologies, thus decreasing the great dependence on unstably priced fossil fuels.

Philip Rutberg, who conducted the IEE RAS from its beginning, was awarded the Peter Marks Medal in 2008 for his contribution in developing the Electromagnetic Launch technology and the Global Energy Prize in 2011, in recognition for his Plasma Energy technology research and fundamental developmental work.

Replicable worldwide

Reduction of 0.97 ton of CO2 eq per MWh of power generated from combines cycle (syngas-steam) in substitution of fuel

Creates new quality jobs

Saves 424,000 liters of diesel per MW annually

Plasmatronic® is DIOXINS and FURANS free

Reduction of 1 ton of CO2 eq per 1 ton of waste processed

Eliminates waste accumulation

Contributes in a decisive manner to greenhouse gases emissions reduction

Fosters future healthy generations in every sense

High profitable projects accessible to developing countries

info@steel-mc.com